- Dedication and determination is key to success and CNC Times team is evident to it - FARO Business Technologies (I) Pvt Ltd Ms. Amrita Gokhale, FARO Business Technologies Seminar was really very good, please let us know about future seminars. We would like to attend the seminar on 'Machining of the material above 60 HRc like titanum'.

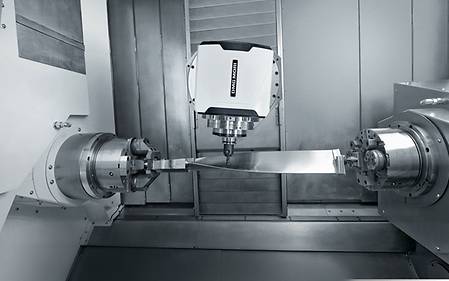

- DMG MORI latest product and topics. Find the best machine that meets your workpiece and machining requirements. 5-axis machines with best-in-class accuracy and high-speed cutting. 5-axis / Multi-axis Machines 2016/04/29 UP. DMU 65 monoBLOCK. Simultaneous 5-axis Machine for Versatile Components. 5-axis / Multi-axis.

5 Axis Mill For Sale, Our Used CNC Mill Machine Inventory Are Under Power And Ready For Inspection. Brands Include Haas, Mazak, Doosan, Dmg Mori And More. DMU 60 eVo linear - 5 Axis CNC Milling Machines and 5 Axis CNC Milling Centers by DMG MORI. 5 Axis Milling. DMU eVo Series. Every DMG MORI machine can be upgraded with standard automation or with a customised.

Universal milling machines mark the beginning of the leadership of DMG MORI in the world market in the area of 5-axis machining. Whether for the classical 5-sided milling operation or 5-axis machines for the premium class of highly precise simultaneous machining, the availability of a wide series ranging from basic to hightech determines the complete spectrum of an efficient milling technology. Other impressive features include achievable accuracies of below 0.38 µin in space and a variety of workpiece dimensions that can be manufactured – up to 88,185 lb component weight as well as travel paths of up to 19.7 ft.

5 Axis Laser Cnc Dmg Mori Download

On the basis of its five series in the field of universal machining centers with pallet changer, DMG MORI provides the ideal path for its customers to make use of automatic 5-sided machining and even challenging 5-axis simultaneous milling. This process not only ensures productive flexibility, but also high cutting performance and maximum precision coupled with high dynamics and excellent accessibility and ergonomics – additional strong arguments. Apart from the geometrical variety resulting from the 5-axis performance, task-optimized spindle alternatives guarantee perfect general conditions in all the areas of application pertaining the CNC milling technology. The range extends from materials that are difficult to cut, e.g. in the aerospace industry, to those which require highest accuracy and surface quality in the area of tool-making and mold making.